#multi effector

Explore tagged Tumblr posts

Text

『アップライト風に弾いてみる』

20240820

4 notes

·

View notes

Text

We're back after a lovely beach vacation to bring you one of the most talked-about units from the last year: the Chroma Console Multi-Effector from Hologram Electronics!! This pedalboard-in-a-box has more sounds, more tones and more experimentation inside it than you could possibly ever need, and that's just scratching the surface of what it can do...Full Demo out NOW, cheers!!

youtube

#pedaloftheday#hologram#hologramelectronics#chroma#chromaconsole#multieffect#multieffects#guitarpedal#guitarpedals#effectspedals#pedalsandeffects#happyeaster#guitar#pedalboard#guitarist#guitareffects#pedals#effects#knowyourtone#Youtube

8 notes

·

View notes

Text

Cancelled Missions: Testing Shuttle Manipulator Arms During Earth-Orbital Apollo Missions (1971-1972)

In this drawing by NASA engineer Caldwell Johnson, twin human-like Space Shuttle robot arms with human-like hands deploy from the Apollo Command and Service Module (CSM) Scientific Instrument Module (SIM) Bay to grip the derelict Skylab space station.

"Caldwell Johnson, co-holder with Maxime Faget of the Mercury space capsule patent, was chief of the Spacecraft Design Division at the NASA Manned Spacecraft Center (MSC) in Houston, Texas, when he proposed that astronauts test prototype Space Shuttle manipulator arms and end effectors during Apollo Command and Service Module (CSM) missions in Earth orbit. In a February 1971 memorandum to Faget, NASA MSC's director of Engineering and Development, Johnson described the manipulator test mission as a worthwhile alternative to the Earth survey, space rescue, and joint U.S./Soviet CSM missions then under study.

At the time Johnson proposed the Shuttle manipulator arm test, three of the original 10 planned Apollo lunar landing missions had been cancelled, the second Skylab space station (Skylab B) appeared increasingly unlikely to reach orbit, and the Space Shuttle had not yet been formally approved. NASA managers foresaw that the Apollo and Skylab mission cancellations would leave them with surplus Apollo spacecraft and Saturn rockets after the last mission to Skylab A. They sought low-cost Earth-orbital missions that would put the surplus hardware to good use and fill the multi-year gap in U.S. piloted missions expected to occur in the mid-to-late 1970s.

Johnson envisioned Shuttle manipulators capable of bending and gripping much as do human arms and hands, thus enabling them to hold onto virtually anything. He suggested that a pair of prototype arms be mounted in a CSM Scientific Instrument Module (SIM) Bay, and that the CSM "pretend to be a Shuttle" during rendezvous operations with the derelict Skylab space station.

The CSM's three-man crew could, he told Faget, use the manipulators to grip and move Skylab. They might also use them to demonstrate a space rescue, capture an 'errant satellite,' or remove film from SIM Bay cameras and pass it to the astronauts through a special airlock installed in place of the docking unit in the CSM's nose.

Faget enthusiastically received Johnson's proposal (he penned 'Yes! This is great' on his copy of the February 1971 memo). The proposal generated less enthusiasm elsewhere, however.

Undaunted, Johnson proposed in May 1972 that Shuttle manipulator hardware replace Earth resources instruments that had been dropped for lack of funds from the planned U.S.-Soviet Apollo-Soyuz Test Project (ASTP) mission. President Richard Nixon had called on NASA to develop the Space Shuttle just four months before (January 1972). Johnson asked Faget for permission to perform 'a brief technical and programmatic feasibility study' of the concept, and Faget gave him permission to prepare a presentation for Aaron Cohen, manager of the newly created Space Shuttle Program Office at MSC.

In his June 1972 presentation to Cohen, Johnson declared that '[c]argo handling by manipulators is a key element of the Shuttle concept.' He noted that CSM-111, the spacecraft tagged for the ASTP mission, would have no SIM Bay in its drum-shaped Service Module (SM), and suggested that a single 28-foot-long Shuttle manipulator arm could be mounted near the Service Propulsion System (SPS) main engine in place of the lunar Apollo S-band high-gain antenna, which would not be required during Earth-orbital missions.

During ascent to orbit, the manipulator would ride folded beneath the CSM near the ASTP Docking Module (DM) within the streamlined Spacecraft Launch Adapter. During SPS burns, the astronauts would stabilize the manipulator so that acceleration would not damage it by commanding it to grip a handle installed on the SM near the base of the CSM's conical Command Module (CM).

Johnson had by this time mostly dropped the concept of an all-purpose human hand-like 'end effector' for the manipulator; he informed Cohen that the end effector design was 'undetermined.' The Shuttle manipulator demonstration would take place after CSM-111 had undocked from the Soviet Soyuz spacecraft and moved away to perform independent maneuvers and experiments.

The astronauts in the CSM would first use a TV camera mounted on the arm's wrist to inspect the CSM and DM, then would use the end effector to manipulate 'some device' on the DM. They would then command the end effector to grip a handle on the DM, undock the DM from the CSM, and use the manipulator to redock the DM to the CSM. Finally, they would undock the DM and repeatedly capture it with the manipulator.

Caldwell Johnson's depiction of a prototype Shuttle manipulator arm with a hand-like end effector. The manipulator grasps the Docking Module meant to link U.S. Apollo and Soviet Soyuz spacecraft in Earth orbit during the Apollo-Soyuz Test Project (ASTP) mission.

Johnson estimated that new hardware for the ASTP Shuttle manipulator demonstration would add 168 pounds (76.2 kilograms) to the CM and 553 pounds (250.8 kilograms) to the SM. He expected that concept studies and pre-design would be completed in January 1973. Detail design would commence in October 1972 and be completed by 1 July 1973, at which time CSM-111 would undergo modification for the manipulator demonstration.

Johnson envisioned that MSC would build two manipulators in house. The first, for testing and training, would be completed in January 1974. The flight unit would be completed in May 1974, tested and checked out by August 1974, and launched into orbit attached to CSM-111 in July 1975. Johnson optimistically placed the cost of the manipulator arm demonstration at just $25 million.

CSM-111, the last Apollo spacecraft to fly, reached Earth orbit on schedule on 15 July 1975. By then, Caldwell Johnson had retired from NASA. CSM-111 carried no manipulator arm; the tests Johnson had proposed had been judged to be unnecessary.

That same month, the U.S. space agency, short on funds, invited Canada to develop and build the Shuttle manipulator arm. The Remote Manipulator System — also called the Canadarm — first reached orbit on board the Space Shuttle Columbia during STS-2, the second flight of the Shuttle program, on 12 November 1981."

source

#Apollo–Soyuz#Apollo Soyuz Test Project#ASTP#Apollo CSM Block II#CSM-111#Rocket#NASA#Apollo Program#Apollo Applications Program#Canadarm#Shuttle Manipulator Arms#Skylab Orbital Workshop#Skylab OWS#Skylab#Skylab I#Skylab 1#SL-1#Space Station#Apollo Telescope Mount#ATM#Cancelled#Cancelled Mission#my post

42 notes

·

View notes

Text

Unlocking Precision in Robotics with Dynaflex: A Dynalog-US Innovation.

Precision is paramount in today's fast-paced world of automation, with industries such as aerospace, automotive, electronics, and advanced manufacturing requiring robot systems to function with precision, in order for the process to deliver quality and consistent performance. This is where Dynatrol-US Dynaflex provides an unparalleled solution to improve robot calibration and motion control for industrial environments.

So, what exactly is Dynaflex?

Dynaflex is sophisticated real-time calibration developed by Dynalog-US- a leader in robotic accuracy solutions. These advanced dynamic performance assessment tools were developed specifically for robot systems. Dynaflex measures the dynamic performance (how robots behave while they operate), versus static calibration tools (preset calibration baked into the robots programming) by evaluating robot compliance and flexibility in real-time. This type of dynamic assessment provides potential for accuracy to industries where tolerances must be tight and conditions demand high levels of performance reliability.

Simply put Dynaflex gives practitioners visibility and insight into how a robot responds dynamically while at work and if sufficient stress or force signatures, behaviour is exhibited. In many cases, this is no different than creating significant and costly rework..

Why is Dynaflex so Important?

When robots perform jobs such as welding, painting, and assembling, even the most minor deviation in motion can create defects or misalignment. Traditional calibration methods consider positioning, but often don't consider the dynamic changes in robot posture due to many different factors such as: gravity, speed and payload. Dynaflex effectively takes calibration to the next level by adding dynamic variables to the calibration equation.

With the Dynaflex system, manufacturers can:

Measure and minimize robot compliance (flexibility under load)

Achieve better path accuracy with complex work processes

Validate robot performance in real-world conditions

Identify mechanical anomalies before they can become major catastrophes

Maximize repeatability and process consistency

These are meaningful relationships to ensure that the robot moves correctly on paper, but that it also can perform accurately on the production floor.

How Does Dynaflex Work?

Dynaflex implements a series of highly sensitive measurement tools and calibration routines that allow engineerings to visualize how the end effector of a robot moves while under load, or at high speed. By measuring real-time flexing, oscillation and inertia, Dynaflex creates a comprehensive map of the robot's behavior.

Once the data has been collected, the data is used to adjust the robot's motion algorithms and account for mechanical variation.

Who is Dynaflex for?

Dynaflex is ideal for companies and industries that expect critical congruency and which themselves use robotic automation, including:

Automotive manufacturing

Aerospace and defence

Medical devices

Electronics assembly

Metal fabrication

3D printing and additive manufacturing

If your company relies on multi-robot cells, automated welding cells, or pick-and-place systems, introducing Dynaflex to your calibration operations will provide great benefit.

Dynalog-US: The Experts in Robot Calibration

Dynalog-US was founded to provide accurate and reliable robotic systems and has been a leader in robot performance technology for several decades. Their products are being used by leading world manufacturers, many of whom are in the Fortune 500.

Whether it is for robotic inspection, Tool Center Point (TCP) calibration or improving robot cell accuracy, Dynalog has a history of introducing products to the marketplace that demonstrate thoughtful engineering, industry leading performance, and great customer support.

Dynalog's market leading solutions, to include Dynaflex, come with documentation, field training, and technical consulting, which is more than just selling a product; Dynalog provides a partnership to achieve your production success.

Many companies have seen measurable improvements after adding Dynaflex to their robotic workflow:

Up to 40% improvement in path accuracy Considerably less joint stress and less component wear Reduction of rework and scrap percentage Faster ROI from robotic systems

One aerospace customer even found that Dynaflex helped them to achieve their tolerance requirements that they previously thought could be accomplished only with standard robots or off-the-shelf robotic equipment.

Future of Robotic CalibrationAs AI, machine Learning, and Industry 4.0 technologies evolve, the need for ongoing performance validation to and compliance will become more valuable. Also, autonomous systems will validate performance more often, and human interventions will be using tools like Dynaflex to ensure safety, quality, and efficiencies.

With Dynaflex by Dynalog-US, businesses now have a scalable and future-proof calibration platform to leverage for future use and to enhance work processes while accomplishing productivity and accuracy improvements in the immediate.

Conclusion

When you invest in robots, investing in robot performance has to be a given. Properly calibrating robot performance starts with the initial calibration when it is stationary, when it is in motion, while it is under load, and evaluating at the full-speed capability.

Dynaflex by Dynalog-US is a calibration device that provides the measurement data (metrics) to give you a competitive advantage for an ever-evolving automated world.

Ready to take the next step in robotic precision? Visit www.dynalog-us.com to learn more about Dynaflex and schedule a consultation with the experts at Dynalog-US.

#Dynaflex#Dynalog-US#Robot Calibration#Robotic Accuracy#Industrial Automation#Robot Compliance#Dynamic Robot Calibration#Robot Motion Control#Manufacturing Technology#Industry 4.0#Advanced Robotics#Robot Performance#Calibration Systems#Automation Solutions#Robot Path Accuracy#Robot Inspection Tools#Robot Flexibility Measurement#Dynaflex Calibration#Robotic Workflow Optimization#Robotic Precision Engineering

0 notes

Text

CNC Machined Parts: Precision, Performance, and Industrial Advantage

CNC Machined Parts: Precision, Performance, and Industrial Advantage

In the world of precision engineering, CNC machined parts have become the cornerstone of innovation, reliability, and repeatability. From aerospace components to medical devices, CNC machining enables the production of high-accuracy parts that meet the most stringent industrial standards.

What Are CNC Machined Parts?

CNC (Computer Numerical Control) machined parts are components manufactured using automated, pre-programmed tools and machinery. This subtractive process removes material—typically from metals like stainless steel or aluminum—to shape the final part with remarkable precision.

CNC machines interpret CAD (Computer-Aided Design) models and convert them into precise movements across multiple axes. The result? Parts that meet exact design specifications, every time.

Key Advantages of CNC Machined Parts

1. High Dimensional Accuracy

CNC machining allows for tolerances as tight as ±0.001 inches. This is essential for industries like aerospace, where precision equals safety.

2. Superior Surface Finish

Machined parts often require minimal post-processing, thanks to high-speed spindles and accurate tool paths.

3. Repeatability Across Batches

Once a CNC program is created, it can be reused indefinitely. This ensures batch-to-batch consistency for mass production.

4. Complex Geometries

Multi-axis CNC machines (like 4-axis or 5-axis machining centers) can manufacture intricate geometries that are impossible with manual processes.

5. Material Versatility

From stainless steel and aluminum to exotic alloys and engineering plastics, CNC machines support a wide range of materials without compromising on quality.

Applications of CNC Machined Parts

Aerospace: Engine housings, fuel system components, and brackets

Medical: Surgical tools, implant components, diagnostic housings

Automotive: Transmission parts, chassis mounts, intake systems

Robotics & Automation: End effectors, custom enclosures, precision joints

Oil & Gas: Valve components, pump casings, flanges

CNC Machined Parts in India: A Rising Global Hub

India is rapidly becoming a leading supplier of precision CNC components, offering high-quality production at globally competitive costs. With access to skilled engineers, modern machinery, and a growing export network, Indian CNC machining companies are serving clients across Europe, North America, and Southeast Asia.

One such standout is Robocon CNC Pvt. Ltd., based in Pune, India.

Why Choose Robocon CNC Pvt. Ltd.?

Robocon CNC specializes in manufacturing custom CNC machined parts for a wide range of industries. With a fully equipped facility housing advanced CNC and VMC machines, the company delivers precision parts in materials like stainless steel (SS304L, SS316L), aluminum, and exotic alloys.

Key Offerings:

Prototype to full-scale production

Tight-tolerance machining

In-house quality control systems

On-time global delivery

Competitive pricing from India

Whether you're developing new products or looking to optimize your supply chain, Robocon CNC Pvt. Ltd. is your trusted partner in precision manufacturing. Visit https://roboconcnc.com to learn more.

Final Thoughts

As industries evolve toward higher performance and miniaturization, CNC machined parts play a vital role in ensuring functionality, precision, and longevity. With the right manufacturing partner, businesses can achieve product excellence and supply chain resilience. For companies seeking world-class CNC machining services from India, Robocon CNC offers the perfect blend of quality, technology, and value.

1 note

·

View note

Text

Multi-omics approaches define novel aphid effector candidates associated with virulence and avirulence phenotypes

Background: Compatibility between plant parasites and their hosts is genetically determined by both interacting organisms. For example, plants may carry resistance (R) genes or deploy chemical defences. Aphid saliva contains many proteins that are secreted into host tissues. Subsets of these proteins are predicted to act as effectors, either subverting or triggering host immunity. However, associating particular effectors with virulence or avirulence outcomes presents challenges due to the combinatorial complexity. Here we use defined aphid and host genetics to test for co-segregation of expressed aphid transcripts and proteins with virulent or avirulent phenotypes. Results: We compared virulent and avirulent pea aphid parental genotypes, and their bulk segregant F1 progeny on Medicago truncatula genotypes carrying or lacking the RAP1 resistance quantitative trait locus. Differential gene expression analysis of whole body and head samples, in combination with proteomics of saliva and salivary glands, enabled us to pinpoint proteins associated with virulence/avirulence phenotypes. There was relatively little impact of host genotype, whereas large numbers of transcripts and proteins were differentially expressed between parental aphids, likely a reflection of their classification as divergent biotypes within the pea aphid species complex. Many fewer transcripts intersected with the equivalent differential expression patterns in the bulked F1 progeny, providing an effective filter for removing genomic background effects. Overall, there were more upregulated genes detected in the F1 avirulent dataset compared with the virulent one. Some genes were differentially expressed both in the transcriptome and in the proteome datasets, with aminopeptidase N proteins being the most frequent differentially expressed family. In addition, a substantial proportion (27%) of salivary proteins lack annotations, suggesting that many novel functions remain to be discovered. Conclusions: Especially when combined with tightly controlled genetics of both insect and host, multi-omics approaches are powerful tools for revealing and filtering candidate lists down to plausible genes for further functional analysis as putative aphid effectors. http://dlvr.it/TBJcD2

0 notes

Text

How to Download Image-Line FL Studio 20.9.2 Producer Edition (Windows)

FL Studio 20.9.2 Producer Edition, developed by Image-Line, is a groundbreaking music production software designed for Windows users. This full version software is available for download, offering lifetime activation. It supports a variety of formats, including AAX, VST3, VST, VST2 AU, and Standalone, ensuring flexibility for different production needs.

Tech Specs (Windows Only)

Software Type: Music Software

Platform: Windows Only

Upgrade/Full Version: Full Unlocked

Download/Boxed: Download

License Type: Lifetime Activation

Format: AAX, VST3, VST, VST2 AU, Standalone

Hardware Requirements – PC: Intel / AMD Multi-core CPU, 4GB RAM minimum

OS Requirements – PC: Windows 10 or later

An Impressive Array Of Powerful New Features

Celebrating the 20th anniversary of FL Studio, Image-Line has bypassed versions 13–19, releasing a significant update straight to version 20.9.2. This version supports time signatures and allows unlimited time signature changes, easing the creative process. The in-situ rendering (freezing) feature reduces the load on your computer, while multiple arrangements let you manage audio, automation, and pattern clips efficiently. The plug-in delay compensation feature ensures a seamless mixing experience, complemented by a refined Graph Editor, “Legacy” Precomputed FX, an upgraded Channel Sampler, and numerous new and updated plug-ins. Additionally, FL Studio now supports Mac with full VST and AU compatibility, enhancing its versatility.

Tons Of Virtual Instruments

FL Studio 20.9.2 Producer Edition comes with 13 virtual synthesizers, offering a vast range of sounds from acoustic/synth bass to electric guitar and plucked strings. It includes powerful sampler tools like a piano and beat-slicing capabilities. The software’s browser simplifies sound searching by category, providing an intuitive user experience. The built-in instruments deliver high-quality sounds, catering to both traditional and electronic music production needs.

Full-Featured Music Production Environment

FL Studio offers flexible audio tools for beat-slicing, time-stretching, chopping, and editing audio. The enhanced Edison Wave Editor provides spectral analysis, convolution reverb, loop-recording, and more. Each track can accommodate up to eight effects and be routed to other audio tracks, offering immense creative flexibility. Included effects cover delay, distortion, EQ, filtering, phasing, flanging, chorus, vocoding, and reverb. Mastering tools such as multiband compression/limiting and parametric EQ are also provided.

Included Instrument And Generator Plug-Ins

Automation: Automation Clip Generator, Envelope Controller, Keyboard Controller

Sample Playback/Manipulation: Audio Clip Generator, BooBass, Channel Sampler, DirectWave Player, FL Keys, Fruity Pad Controller (FPC), Granulizer, Slicer, Slicex, Wave Traveller

Synthesizers: 3x OSC, Autogun, BassDrum, BeepMap, Drumpad, Fruity Kick, Fruity DX10, Groove Machine Synth, MiniSynth, Speech Synthesizer, FL FlowStone, Sytrus, Wasp/WaspXT

Tools/Generators: Control Surface, Patcher, Dashboard, Fruity Video Player2, Layer Channel, MIDI Out, ReWired, FL Studio Mobile Plug-in

Included Effects Plug-Ins

Automation: Formula Controller, Peak Controller, X-Y Controller

Compressors/Limiters: Fruity Compressor, Fruity Limiter, Fruity Multiband Compressor, Soft Clipper, Maximus, Soundgoodizer

Delay/Echo: Delay, Delay 2, Delay 3, Delay Bank

Distortion: Blood Overdrive, Fast Dist, Fruity Squeeze, WaveShaper

EQ: Edison Equalize Function, Convolver, EQUO, Fruity 7 Band EQ, Fruity Parametric EQ, Fruity Parametric EQ2

Filtering: Fast LP, Filter, Free Filter, Love Philter

Vocoder: Vocodex

Phasing/Flanging/Chorus: Chorus, Phaser, Flanger, Flangus

Reverb: Convolver, Reeverb, Reeverb 2, Edison Convolution Reeverb

Multi FX: Effector (12 FX)

Tools: Control Surface, Balance, Big Clock, Center, Patcher, dB Meter, HTML NoteBook, LSD, Mute 2, NoteBook, PanOMatic, Phase Inverter, Scratcher, Send, Stereo Enhancer, Stereo Shaper

Visualization: Fruity Dance, Spectroman, Wave Candy, ZGameEditor Visualizer

Download FL Studio 20.9.2 Producer Edition

For a seamless music production experience, download Image-Line FL Studio 20.9.2 Producer Edition (Windows) from the following link: Download Now.

1 note

·

View note

Text

Royal New Zealand Navy Receives Operational Training on SeeByte’s Mission Management System

SeeByte, the global leader in smart software solutions for robotic and autonomous systems, successfully delivered on-site training of their multi-domain mission management system, SeeTrack, to the Royal New Zealand Navy (RNZN). RNZN are using SeeTrack for in-field mission planning and post-mission analysis using their fleet of HII REMUS 300 and 100 vehicles. The RNZN Command team need only learn a single way of planning and monitoring missions regardless of the different manufacturers or types of vehicles, sensors, and effectors being employed. Managing multiple platforms and sensors at one time from SeeTrack’s common user interface will help to maximise the capabilities of RNZN’s uncrewed systems and offers a level of interoperability while working together with other nations.

SeeByte, the global leader in smart software solutions for robotic and autonomous systems, successfully delivered on-site training of their multi-domain mission management system, SeeTrack, to the Royal New Zealand Navy (RNZN). RNZN are using SeeTrack for in-field mission planning and post-mission analysis using their fleet of HII REMUS 300 and 100 vehicles. The RNZN Command team need only learn…

View On WordPress

0 notes

Text

Blog 3: Unreal Engine 5.4's Motion Graphics and Realtime Rendering

INDUSTRY PRACTICE

Unreal Engine 5.4 is a shining example of innovation in the constantly changing field of digital creation, providing a wealth of improvements in a variety of areas. The most recent version keeps expanding the possibilities for creating digital video, from the revolutionary developments in Nanite to the specialized tools for motion graphics and virtual production.

Nanite: Redefining Detail and Performance

Nanite, the virtualized micropolygon geometry system at the core of Unreal Engine 5.4, gets a lot of improvements. The Experimental Tessellation function, which allows artists to add minute elements like bumps and cracks during render time without changing the original geometry, is one of the most noteworthy additions. This enables artists to produce scenes with previously unheard-of degrees of complexity and realism. Moreover, the implementation of Nanite compute materials for software variable rate shading (VRS) yields significant performance improvements, boosting productivity without sacrificing visual quality. Furthermore, new possibilities are made possible by support for spline mesh operations, especially when it comes to jobs like building highways on landscapes. Now that UV interpolation can be turned off, vertex animated textures can be easily incorporated with Nanite geometry, increasing the animation's potential.

Motion Graphics: Streamlined Creativity

For those who work in motion graphics, Unreal Engine 5.4 offers a new mode called Experimental Motion Design. Featuring specialised tools for creating intricate 2D motion graphics, this mode claims to improve productivity and enrich the user experience. With an all-inclusive toolkit that includes animators, modifiers, effectors, and 3D cloners, motion designers can now unleash their creativity with never-before-seen ease and efficiency.

Virtual Production: Empowering Filmmakers

With Unreal Engine 5.4, filmmakers who are adopting virtual production will benefit from a number of updates meant to improve workflows and increase platform compatibility. In addition to its current iOS platform compatibility, the Virtual Camera tool now has Android support and is considered Production-Ready. Virtual Camera workflows provide flexibility and accessibility across multiple operating systems, and they are fully supported on macOS as well. A new Experimental toolkit for VR Scouting uses the XR Creative Framework to support OpenXR head-mounted displays (HMDs), like Oculus and Valve Index. Virtual scouting workflows for immersive productions are set to be revolutionized by this customizable toolkit, which promises an enormously improved user experience.

Depth of Field Compensation was introduced for ICVFX (In-Camera Visual Effects) to provide accurate control over the depth of field falloff of digital content rendered by display. This leads to improved visual consistency and realism, especially for close-up beauty shots. By dividing the workload among several GPUs and hardware resources, Multi-Process Inner Frustum improves rendering efficiency and further optimizes performance in demanding production scenarios.

0 notes

Link

#actuatorsinrobotics#AdvancedRoboticGrippers#AdvancedRoboticsEngineering#AutomationTechnology#collaborativerobots#CustomRoboticSolutions#EndEffectors#FlexibleRobotSystems#Grippertechnology#industrialrobots#KinematicsinRobotics#ManipulatorDynamics#MechanicalEngineering#MotionControl#PrecisionRobotics#ProgrammableManipulators#RobotManipulators#RoboticArmDesign#RoboticArms#RoboticAssemblyAutomation#RoboticAutomationSystems#RoboticControlSystems#RoboticEfficiencyEnhancement#RoboticManipulationTechniques#RoboticSystemIntegration

0 notes

Text

Ananka

Q1) Fasteners in Robotics and Automation: Advancing Technology

Ans) Fasteners play a pivotal role in the field of robotics and automation, where precision, reliability, and efficiency are paramount. As technology continues to advance, fasteners have evolved to meet the specific demands of robotic and automated systems, enabling the development of sophisticated and cutting-edge applications. Here are some ways fasteners are advancing technology in robotics and automation:

1. Miniaturization and Lightweight Designs: Fasteners used in robotics and automation have become increasingly smaller and lighter, allowing for compact and agile robot designs. Miniaturization not only reduces the overall weight of robotic components but also enhances their flexibility and maneuverability, enabling robots to navigate tight spaces and perform intricate tasks.

2. High-Strength Materials: Advancements in materials science have led to the development of fasteners made from high-strength alloys and composites. These materials offer excellent mechanical properties, allowing fasteners to withstand heavy loads and stresses, which is crucial for the reliable operation of robotic arms and components.

3. Quick-Change Fasteners: In automated production lines and robotic applications that involve frequent tool changes, quick-change fasteners enable rapid and efficient swapping of end effectors or tooling. This reduces downtime and increases productivity, making automated processes more seamless and responsive.

4. Modular Assembly: Modular fastening systems simplify the construction and maintenance of robotic and automation systems. Modular designs allow for easy disassembly and reconfiguration, making it simpler to replace components or add new functionalities to the robot without extensive modifications.

5. Vibration Damping and Noise Reduction: Robots and automated machinery often generate vibrations and noise during operation. Fasteners with vibration-damping features help mitigate these issues, leading to quieter and smoother robotic movements, as well as reducing wear and tear on the system.

6. Integrated Sensors and Electronics: Some advanced fasteners are designed with built-in sensors or electronics, contributing to the development of smart and interconnected robotic systems. These fasteners can monitor variables like torque, tension, or temperature, providing valuable data for real-time monitoring and predictive maintenance.

7. Magnetic Fastening Solutions: Magnetic fasteners are becoming popular in robotic end effectors and grippers. They enable secure and non-contact holding of objects, allowing robots to handle delicate or irregularly shaped items with precision and care.

8. Self-Locking Fasteners: In high-vibration environments, self-locking fasteners prevent unintentional loosening and maintain joint integrity over extended periods, ensuring the long-term reliability and stability of robotic components.

9. Environmentally Resilient Fasteners: Robotics and automation are increasingly being deployed in extreme environments, such as space exploration or harsh industrial settings. Fasteners with special coatings or materials that resist corrosion, extreme temperatures, or radiation play a crucial role in ensuring the longevity and performance of robots in such conditions.

10. Multi-Material Fastening: With the use of diverse materials in robot construction, such as plastics, metals, and composites, fasteners that can securely join dissimilar materials have gained importance. These fasteners facilitate the integration of various components without compromising structural integrity.

The continuous evolution of fasteners in robotics and automation is driving advancements in the capabilities and applications of robotic systems. From enhancing precision and versatility to improving safety and reliability, innovative fastening solutions contribute significantly to the progress of this transformative technology. As robotics and automation continue to reshape industries, fasteners will remain a fundamental element in pushing the boundaries of what robots can achieve in various sectors, from manufacturing and healthcare to exploration and beyond.

Stainless Steel Bolt and Nut Manufacturers in India

Q2) Fasteners in Historical Engineering Marvels: From Bridges to Buildings

Ans) Throughout history, fasteners have played a crucial role in the construction of engineering marvels, from impressive bridges to towering buildings. These innovative connectors have enabled the realization of ambitious architectural projects that have stood the test of time. Here are some examples of how fasteners have been instrumental in the creation of historical engineering marvels:

1. Ancient Bridges:

In ancient civilizations, such as the Roman Empire, stone arch bridges were constructed using a combination of gravity and interlocking stones without the use of fasteners. The precision in cutting and shaping stones allowed for stable and durable bridge structures, some of which still stand today.

2. Medieval Cathedrals:

Medieval cathedrals in Europe, like the Notre Dame Cathedral in Paris, employed wooden pegs and mortise and tenon joints to join massive stone blocks and wooden beams, providing stability and strength in the absence of modern fasteners.

3. Iron Bridges:

In the 18th and 19th centuries, the Industrial Revolution brought advancements in iron production, leading to the construction of iron bridges like the Iron Bridge in Shropshire, England. These bridges utilized iron bolts and rivets to connect iron components, pioneering the use of fasteners in large-scale structures.

4. Eiffel Tower:

The iconic Eiffel Tower, completed in 1889, was assembled using over 2.5 million rivets. The use of rivets allowed for the efficient construction of this steel lattice structure, which has become a symbol of architectural innovation.

5. Empire State Building:

The Empire State Building, completed in 1931, utilized various fasteners, including nuts and bolts, to join its steel frame. These fasteners played a critical role in assembling the 102-story skyscraper, making it one of the tallest and most iconic buildings of its time.

6. Golden Gate Bridge:

The Golden Gate Bridge, completed in 1937, utilized over 1.2 million rivets to connect its steel components. The strength and reliability of these riveted connections have contributed to the bridge's endurance and structural integrity.

7. Sydney Opera House:

The Sydney Opera House, completed in 1973, features an innovative sail-like design composed of precast concrete panels. Stainless steel brackets and fasteners were used to connect these panels, contributing to the distinctive appearance of this architectural masterpiece.

8. Burj Khalifa:

The Burj Khalifa, completed in 2010, is the tallest building in the world. Its construction relied on high-strength bolts and fasteners to secure its steel and concrete components, ensuring stability at extreme heights.

9. Millau Viaduct:

The Millau Viaduct in France, completed in 2004, utilized specialized high-strength fasteners to connect its steel cable-stayed structure, creating one of the tallest bridges in the world.

10. Shanghai Tower:

The Shanghai Tower, completed in 2015, employed advanced fastening technologies to assemble its twisting and tapering form, showcasing the evolution of fasteners in modern architectural design.

In conclusion, fasteners have been essential in the construction of historical engineering marvels, ranging from ancient stone structures to modern skyscrapers. From the simplicity of wooden pegs to the precision of rivets and high-strength bolts, these connectors have enabled architects and engineers to push the boundaries of what is possible in construction and leave behind lasting monuments to human ingenuity and innovation.

ASME Fastener Standards

Q3) Fasteners for Wearable Technology: Comfort and Durability

Ans) Fasteners play a vital role in the design and functionality of wearable technology, ensuring both comfort and durability for users. Wearable devices, such as smartwatches, fitness trackers, and medical wearables, are becoming increasingly popular due to their convenience and ability to collect and analyze data in real-time. Here are some ways fasteners contribute to the comfort and durability of wearable technology:

1. Adjustable Straps: Many wearable devices feature adjustable straps with different fastening mechanisms like buckles, hook-and-loop (Velcro), or magnetic closures. These fasteners allow users to customize the fit of the device, ensuring a comfortable and secure wearing experience.

2. Soft and Lightweight Materials: Fasteners used in wearable technology are often made from soft and lightweight materials to minimize irritation and maximize user comfort during prolonged wear.

3. Sweat and Water Resistance: Wearable devices designed for active use, like fitness trackers, often include fasteners with sweat and water-resistant properties. These features help protect the device and maintain its functionality during exercise or in wet environments.

4. Quick Release Mechanisms: Some wearable devices incorporate quick-release fasteners to facilitate easy removal and attachment. This feature is particularly useful for medical wearables or fitness trackers that need to be taken off for charging or cleaning.

5. Low Profile Designs: Fasteners used in wearable technology are typically designed to be low profile and discreet, preventing any protrusions or discomfort when the device is in direct contact with the skin.

6. Durability and Reliability: Wearable technology is subject to constant movement, bending, and stretching. Fasteners must be durable and reliable to withstand these repetitive motions without compromising the device's integrity.

7. Anti-Snag Design: Fasteners for wearable devices often feature anti-snag designs to prevent them from catching on clothing or other objects, reducing the risk of damage or detachment.

8. Skin-Friendly Coatings: Some wearable devices, especially medical wearables, use fasteners with skin-friendly coatings to minimize allergic reactions or skin irritation in sensitive individuals.

9. Magnetic Fasteners: Magnetic closures are increasingly popular in wearable technology, providing a secure yet easy-to-use fastening solution. Magnetic fasteners can be quickly detached or attached with one hand, enhancing user convenience.

10. Adhesive Fasteners: In some wearable devices, adhesive fasteners are used to secure sensors or components directly onto the skin. These medical-grade adhesives are designed to be gentle on the skin and provide a reliable bond.

In conclusion, fasteners for wearable technology are engineered to prioritize comfort and durability. Through innovative designs, materials, and features, fasteners enhance the overall user experience, allowing people to seamlessly integrate wearable devices into their daily lives while enjoying the benefits of cutting-edge technology.

European Fastener Standards

0 notes

Text

My new gear "NUX MG-300"

Modeling Guitar Processor

Multi-Effects Processor

0 notes

Text

Ancient mediators of innate immunity

Bacteria can become infected by bacteriophages and have developed a range of anti-phage immune pathways to counteract these infections. These pathways are often multi-gene systems encoding proteins that sense and inhibit virion production, and efforts to catalog anti-phage signaling systems in bacteria have revealed that some of these genes share homology with components of eukaryotic immune systems. This suggests that eukaryotes horizontally acquired some innate immune genes from bacteria.

Many components have been identified as homologous between bacteria and humans, including bacterial cyclic-oligonucleotide-based anti-phage signaling systems (CBASS) with human cGAS and STING, and bacterial Viperins and Gasdermins with human Viperin and Gasdermin D. However, SBGrid member Aaron Whiteley and other researchers have been searching for other potential components in bacterial anti-phage signaling systems which could be homologous to immune signaling elements in humans. The researchers demonstrate that bacteria express anti-phage proteins containing a NACHT module, which is an important element of the animal nucleotide-binding domain leucine-rich repeat containing gene family called NLRs. These NACHT proteins are widespread in bacteria and contain a C-terminal sensor, central NACHT module, and N-terminal effector component, acting against both DNA and RNA bacteriophages.

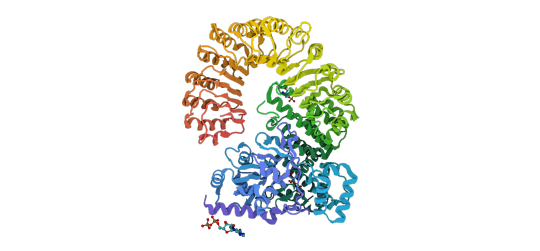

Above: Previously reported structure of NLR family CARD domain-containing protein 4. CC BY SBGrid.

Importantly, they determined that mutations in human NLR which lead to stimulus-independent activation of downstream signaling also activate bacterial NACHT proteins, suggesting that the bacterial and human systems share similar signaling mechanisms. This work identifies NACHT module-containing proteins as ancient innate immune signaling elements and expands our knowledge of homology between bacterial anti-phage immune pathways and eukaryotic immune systems.

Read more about this work in Cell.

#cell#immunology#science#nature#microbiology#sbgrid#sbgrid member research#biomedical research#Biomedical Science

7 notes

·

View notes

Photo

Rhythmic Continuum V1.0 webinar: Cinema 4D + Corona + Keyshot with @mihaiodes - If you can’t attend the live date and time you will still get access to the recording by registering! - Register Now, link in bio or: https://designmorphine.com/education/rhythmic-continuum-v1-0 - Rhythmic Continuum V1.0 will focus on creating intricate and rhythmical fluid geometries by using Cinema 4D procedural toolsets such as MoGraph generators and effectors combined with topological volumetric and smart materials. The aim will be to become accustomed to a multi-layered workflow starting from modelling a simple object that can be optimized in steps and increased in number and complexity to form fluid patterns and larger landscape like geometries. . . . . . . #cinema4d #mograph #3dmodel #3dmodeling #zahahadidarchitects #fluidity #architecture #architecturedesign #parametricarchitecture #parametricism #parametricart #generativedesign (at 𝓣𝓱𝒆 𝓤𝒏𝒊𝓿𝒆𝒓𝒔𝒆) https://www.instagram.com/p/Cl9Oo0yvCVf/?igshid=NGJjMDIxMWI=

#cinema4d#mograph#3dmodel#3dmodeling#zahahadidarchitects#fluidity#architecture#architecturedesign#parametricarchitecture#parametricism#parametricart#generativedesign

5 notes

·

View notes

Text

Last week's top 20 videos (2023, week 02)

Top 20 videos last week (January 8-14)

Danny Mattin with Organ Grinder Fish Paper (by Lounsberry)

Strymon El Capistan dTape V2 vs V1 vs Roland RE-201 & Fender Space Delay (by That Pedal Show)

Playing AC/DC with the #BeatBuddy #shorts (by Singular Sound)

#Ibanez DL10 Digital Delay Quick Pedal #Demo #shorts (by mrtolex)

The Smiley is inspired by the first-era, silicon model Arbiter fuzzes. (by JHS Pedals)

JAM pedals | Red Muck (by JAM Pedals)

Jay P testing EvH sound met cool & SuperDrive (by Lex Bos)

?Vol.58??????? Jake Cloudchair??Myriad Fuzz???????? (by The Effector Book)

Vintage 1970 Shin-Ei Uni-Vibe Repair/Restoration Part 4 "How it Should Sound" (by Argenziano Effetti)

Tube booster TubeZoid-B 12AX7 version (by SviSound)

A portable CD player inside a digital delay pedal? (CSIDMAN) (by Anne Sulikowski)

Playing a $5000 Arbiter Fuzz Face & 1963 Stratocaster #shorts (by Pedal Pawn)

Bien plus qu'un compresseur | Origin Effects Cali76 (Stacked Ed.) (by Tone Factory)

Strymon El Capistan V2 ????? ????? (by String6Channel)

Ibanez EM5 Echomachine Teardown! See what's inside! (by Gray Bench Electronics)

Electro-Harmonix Small Stone v Bad Stone: Which is the swirled champion? (by Dickie's 90-Second Pedal Demos)

The Alpha Omega Pi, the Deluxe Big Muff Pi is the most versatile BMP ever! (by Electro-Harmonix)

Sonicake 5th Dimension 11-Mode Digital Modulation Guitar Effects Pedal (by Sonicake)

Conn Multi-Vider Vintage Multi Effects (Octave, Fuzz, Filter) (by Francisco Sanchez de la Vega)

Texas Square face.. Blue. (by Tone Log Vintage Replicas)

Overviews of the previous weeks: https://www.effectsdatabase.com/video/weekly

from Effects Database https://bit.ly/3XndPtS

2 notes

·

View notes